Skalar Instrument Connectivity with Clinisys Laboratory Solutions™

Instrument integration with Laboratory Information Management Systems (LIMS) provides two main beneficial features for laboratories: the optimization of time efficiency and elimination of potential human error. In regulated environments, any increase in automation plays a key role in helping streamline operations and safeguard data integrity.

Our Clinisys Laboratory Solutions™ for clinical, pharmaceutical, environmental, agricultural, toxicology, and public health laboratories, has developed seamless interfaces with many instruments across multiple verticals. Clinisys developed a unique interface with Skalar Analytical B.V., a manufacturer of instruments and robotics sold across many similar verticals.

Automated Data

Productivity demands, while conforming to regulated quality control criteria, have necessitated the push toward automation within the laboratory community.

Automation makes the flow of data more fluid while simultaneously preventing potential errors. Facilitating the automation of instrument sample upload and/or result download optimizes time utilization and provides a seamless tool for eliminating data duplication efforts.

Skalar’s instrumentation is equipped with a robust software platform that may receive sample data directly from a LIMS and provide finalized or a raw data push to a LIMS, based upon the user’s preference. The CP offers uni- and bi-directional interfaces to communicate with instrumentation and has integrated with Skalar’s suite of instruments and robotics.

One-Way Data Push from Instruments to LIMS: An Example

The simplest form of integration is a uni-directional data “dump” of finalized or raw data from instruments into LIMS. This integration typically requires only a simple .CSV or .TXT file from the instrument software to be “married up” to a data parser from the LIMS.

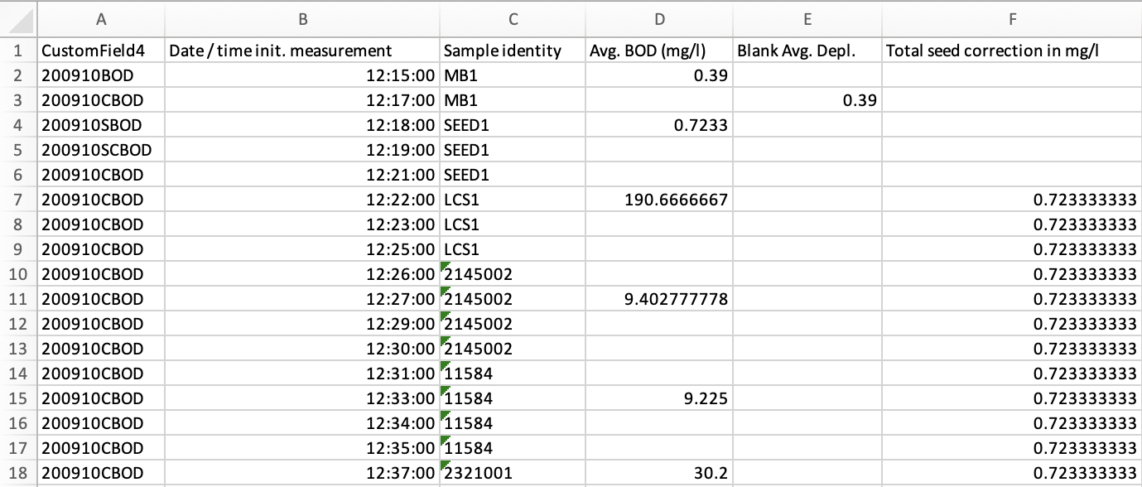

Using the raw data in Skalar Robotics software, a user clicks the export button after review, and a second window pulls up. The user then selects from the upper drop-down menu the export format required. This sets up the user to choose the file export format. The user then clicks on the Save As button, and the directory pops up so the user can select the file location.

From the LIMS side, the data is brought in using a parser. A few different formats for parsing are available depending on the need. A partial example is seen below:

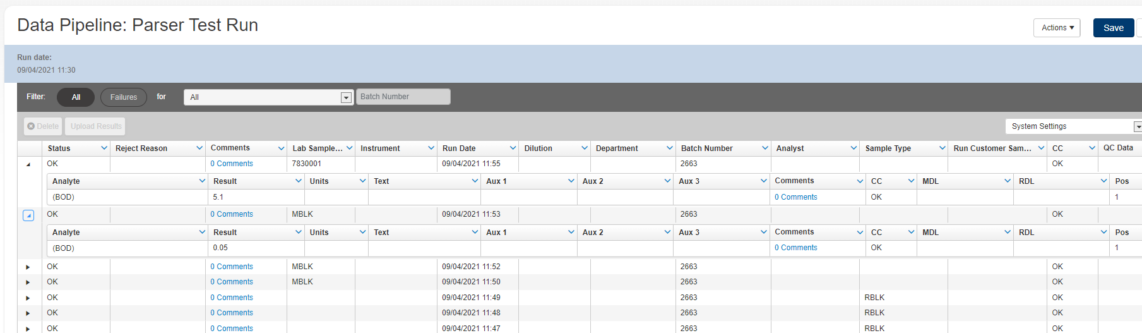

Below is a screenshot of the final data processed into the LIMS from a Skalar BOD instrument:

Bi-directional Communication

To maximize automation where available, the bi-directional interface of instrumentation allows the LIMS to assign samples to a batch and then download the batch sequence to the instrumentation. CP can produce multiple export files, with CSV and Excel formats being the most common.

Within the Skalar Robotics software, the user selects New Analysis. The first screen allows users to choose the trays required. Then the user clicks the Import button on the right side of the screen, and the window below pops up. The user will then select the correct import layout to populate the directory where the import file from LIMS is located. The user selects the valid file in the folder and presses Load Preview to verify that the data in the file is accurate. The user then clicks the import button, and the data is pulled into the instrument’s software.

Once data is imported, the user clicks the Validate button, and the dilutions for each client line are populated from the software’s historical dilutions for each client. This action creates the sequence for the analysis run.

Conclusion

Through the utilization of instrument integration with LIMS, laboratories may maximize sample throughput while ensuring good lab practices. Completing the circle of laboratory automation helps ensure quality and guarantees efficiencies.

Click here to find out more about the Clinisys Platform.